About us

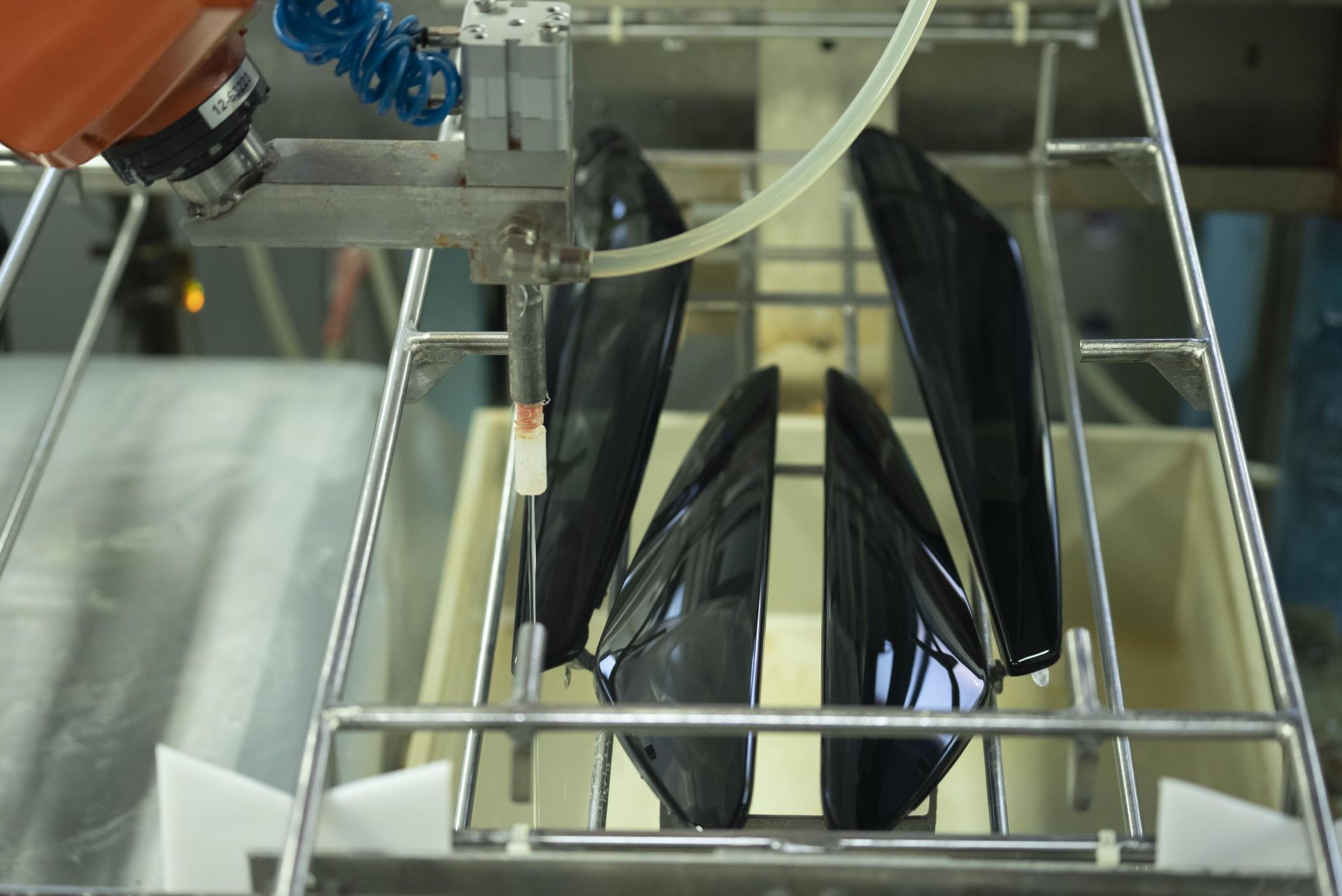

Omnia Plastica has been operating in Italy and abroad since 1950 with a group of companies covering the entire supply chain of technical and industrial plastic stock shapes through various technologies ranging from extrusion to anionic polymerisation. The injection moulding and surface treatment departments ensure a complete range of services in the world of technopolymers.

A specific high-tech division (Bell Safety Defence&Security) deals with the design, manufacture and sale of civil and military safety devices such as helmets, shields, etc.